-

Contact Us

- Phone:+86 756 8698786

- Fax:+86 756 8679535

- Email:info@lingkeultrasonics.com

- Addr:NO.3 Pingxi Wu Road, Nanping Technology Park, Zhuhai City, Xiangzhou District, Guangdong Province, China

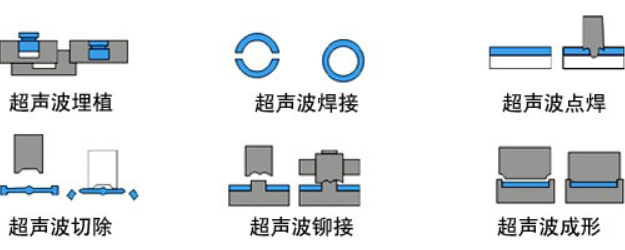

Common functions of ultrasonic welding

Common functions of ultrasonic welding

• ultrasonic fusion

The ultrasonic ultra-high frequency vibration welding head (horn) can produce friction heat on the joint surface of two pieces of plastic under a moderate pressure and melt instantly. The welding strength can be comparable to that of the main body. The proper workpiece and reasonable interface design can achieve watertight and airtight, avoid the inconvenience caused by the use of auxiliary products, and realize efficient and clean fusion.

The design of typical ultrasonic welding surface must have the following two functions:

1. The design of tongue and tenon ensures convenient alignment in welding cycle.

2. The design of welding wire is fine, but there must be enough fusible material to make the welding surface fusible.

The specific design method depends on which workpiece equipment is used for welding. The welding pressure, amplitude and other parameters can be adjusted to ensure that the welding head can contact the welding surface and apply pressure. The lower workpiece is the part receiving the pressure and is placed in the bottom mold. Due to the high frequency of ultrasonic wave generated by the welding head, the upper workpiece generates thermal vibration, so it can be fused with the lower workpiece. After the welding head stops vibrating, the pressure is maintained, so that the melting position is cooled and formed. The whole welding time is mostly less than one second.

• ultrasonic riveting

The horn of ultrasonic ultra-high frequency vibration is pressed on the protruding pin of plastic products to make it heat instantly and melt into the shape of rivet, so that the metal objects are riveted and fixed.

• ultrasonic implant

With ultrasonic ultra-high frequency sound wave vibration, through the conduction of the welding head (horn) and appropriate pressure, the metal parts (such as nuts, screws) are squeezed into the reserved plastic holes in an instant and fixed at the set depth. After completion, the tensile force and torsion can be comparable to the strength of traditional molding in the mold, and the defect of injection damage and slow injection can be avoided.

• ultrasonic spot welding

When two pieces of plastic are to be welded, due to the limited conditions of the welded object, it is impossible to set up a fuse line, so spot welding can be used. The principle is to use the ultrasonic wave to conduct to the front end of the welding head, to pass through the upper plate to the lower plate, so as to achieve the effect of welding, and to spot weld multiple points at the same time, so as to improve the working efficiency.

• ultrasonic removal

The ultrasonic high-speed vibration welding head is used to cut the sharp burr of the plastic part and cut the injection port, so that the plastic part can be separated from the injection channel in an instant, and the manual cutting process can be avoided. The advantages of this method are that the incision is bright and clean without cracking and drawing. The materials suitable for ultrasonic cutting are ABS, PS, acrylic, PC, plastic steel, etc. if the plastic is too soft or elastic, it is not suitable for ultrasonic cutting. (the effect of plastic material is not good before it is cooled when it is just injected)

• ultrasonic forming

• similar to ultrasonic riveting. It is to press the concave welding head on the outer ring of the plastic product, so that the plastic can be melted and formed after high frequency vibration, and then it can be wrapped on the metal object to make it fixed, and the appearance is smooth and beautiful. It is mostly used for the fixed forming of the electronics and speakers, and the lens fixation of cosmetics, etc.